About Vanadium Nitride VN Powder :

Vanadium nitride VN is a compound of vanadium and nitrogen. Vanadium nitride, also known as vanadium-nitrogen alloy, is a new type of alloy additive that can replace ferrovanadium in the production of micro-alloyed steel. It has two crystal structures: one is V3N, a hexagonal crystal structure, with extremely high hardness, with a tiny hardness of about 1900HV and an undetectable melting point; the other is VN, with a face-centered cubic crystal structure, with a tiny hardness of about 1520HV and a melting point of 2360 degrees.

Vanadium nitride is formed during the nitriding process of steel and increases wear resistance. In the nitriding process, another phase V2N (also called vanadium nitride) can be formed together with VN. VN has a cubic rock salt structure. There is also a low-temperature form, which contains V4 clusters. When the vibration mode energy in the high-temperature NaCl-structure phase drops below zero, the low-temperature phase is caused by dynamic instability.

It is a strong coupling superconductor. It is said that nanocrystalline vanadium nitride has the potential to be used in supercapacitors. The properties of vanadium nitride are sensitively dependent on the stoichiometry of the material. Feel free to send an inquiry to get the latest price if you would like to buy Vanadium Nitride VN Powder in bulk.

Product Performance of Vanadium Nitride VN powder:

Vanadium nitride powder prepared by the variable current laser ion beam, chemical vapor deposition, product uniform

particle size distribution, mass production is big, can be a large number of applications to the hard alloy, high surface activity,

can well disperse in the alloy material, dispersion strengthened alloy.

Technical Parameter of Vanadium Nitride VN powder:

| Product Name | MF | Purity | Particle Size | Specific Surface Area

(m2/g) | Volume Density

(g/cm3) | Color |

| vanadium nitride | VN | 99% | 5-10um | 30.2 | 1.29 | gray-black |

Chemical Composition of Vanadium Nitride VN powder:

| VN | N | Si | Fe | Cr |

| 99.5% | 19.5% | 0.04% | 0.14% | 0.004% |

How is Vanadium Nitride VN Powder produced?

A sample made of ammonium metavanadate powder and carbon powder is pre-reduced in a heating furnace, and then the final reduction is performed. After the final reduction is completed, the sample is cooled with the furnace, and the sample obtained is vanadium nitride; During the process, the temperature in the heating furnace is 650-670℃, and the holding time of the heating furnace is 2 to 4 hours. Under the conditions of this temperature and holding time, it can prevent the surface of the sample from melting and hinder the reduction reaction.

After the pre-reduction, the main reduction product of the sample is V2O3, and the rest are carbides and a small amount of VN; in the final reduction process, the sample is kept warm at 1300~1500℃. During the heat preservation process, CO gas and CO gas are generated. It is taken away by the introduced nitrogen, and after the heat preservation is completed, VN is obtained; during the reaction, the nitrogen flow rate is 210~270mL/min, which can not only meet the kinetic conditions of the reduction reaction but also prevent the reaction temperature caused by excessive nitrogen. Reduce, and waste nitrogen;

Applications of Vanadium Nitride VN Powder:

Vanadium nitride has high wear resistance, and vanadium steel can be greatly improved after nitriding treatment.

The comprehensive mechanical properties of high steel such as strength, toughness, ductility and thermal fatigue resistance, and make the steel have good weldability. When the same strength is reached, adding vanadium nitride can save 20-40% of vanadium addition, thereby reducing costs.

Vanadium-nitrogen alloy can be used in structural steel, tool steel, pipe steel, rebar and cast iron. The vanadium-nitrogen alloy used in high-strength low-alloy steel

It can carry out effective vanadium and nitrogen microalloying at the same time, promote the precipitation of carbon, vanadium, and nitrogen compounds in the steel, and more effectively play the role of settlement strengthening and grain refinement.

The addition of vanadium nitride to steel can improve the comprehensive mechanical properties of steel such as strength, toughness, ductility and thermal fatigue resistance, and make the steel have good weldability.

When the same strength is reached, adding vanadium nitride can save 30-40% of vanadium addition, thereby reducing costs. Vanadium-nitrogen alloy can be used in structural steel, tool steel, pipe steel, rebar and cast iron.

The vanadium-nitrogen alloy used in high-strength low-alloy steel can simultaneously carry out effective vanadium and nitrogen microalloying, promote the precipitation of carbon, vanadium, and nitrogen compounds in the steel, and more effectively play the role of settlement strengthening and grain refinement.

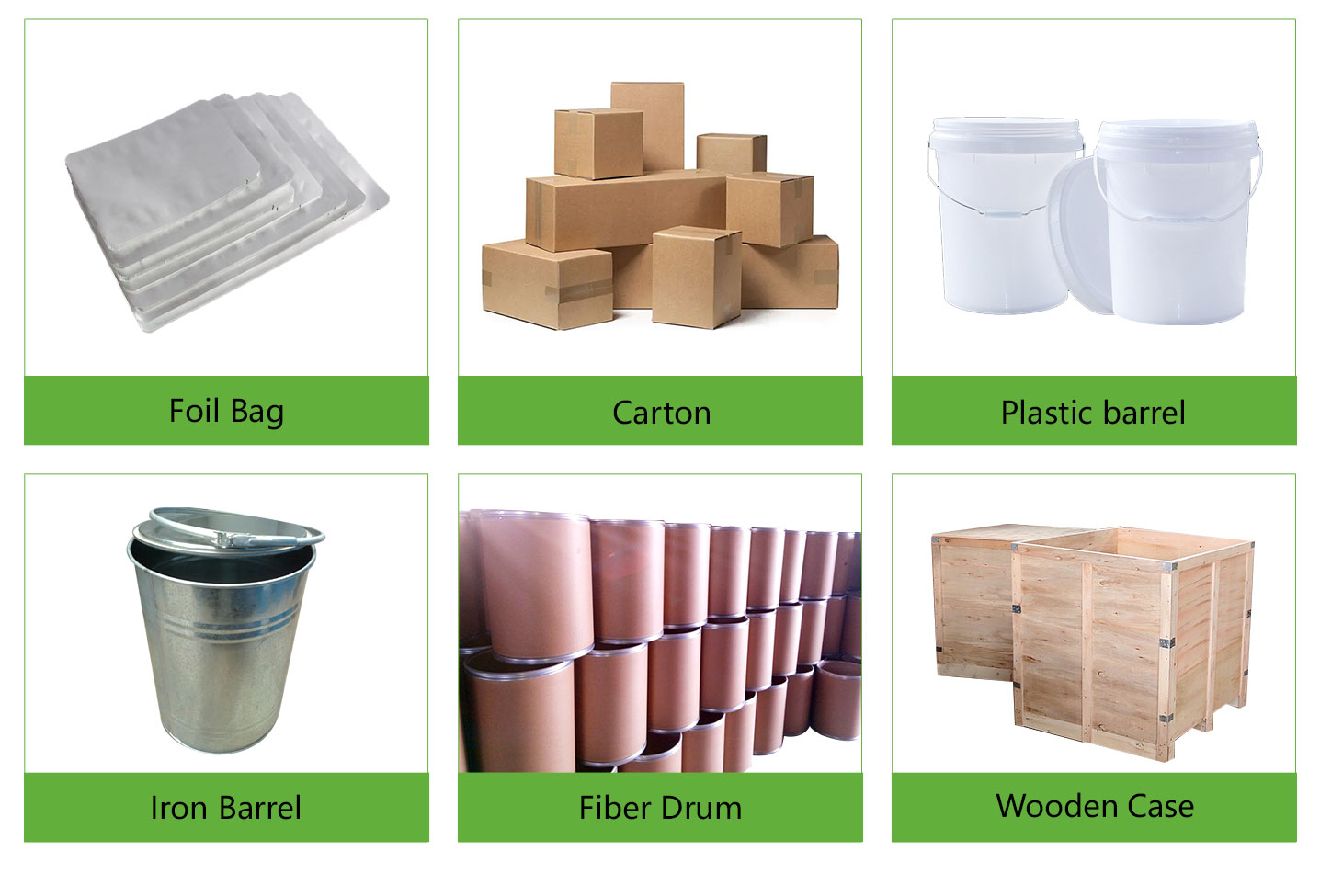

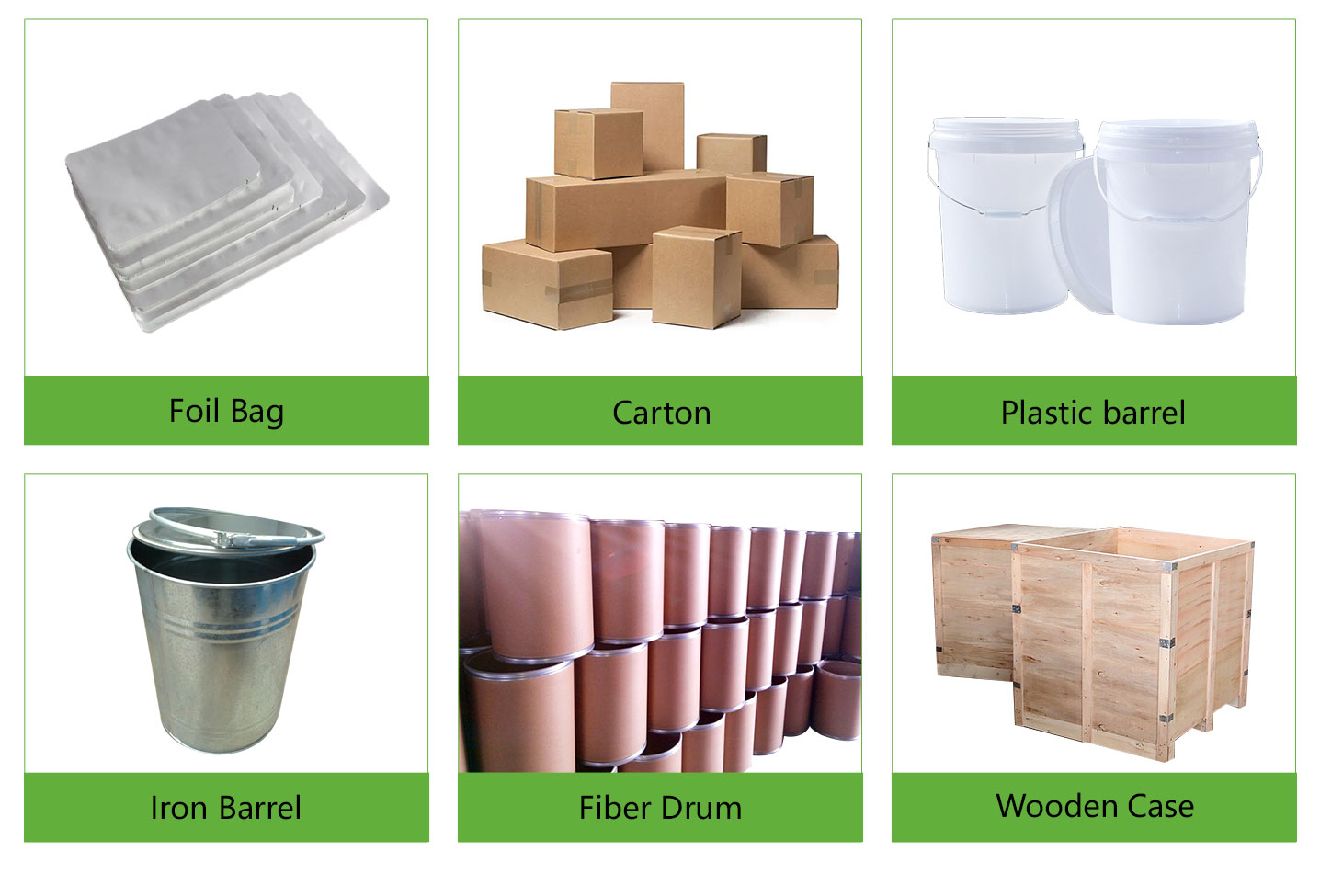

Packing & Shipping of Vanadium Nitride VN powder :

We have many different kinds of packing which depends on the vanadium nitride VN powder quantity.

Vanadium nitride VN powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Vanadium nitride VN powder shipping: could be shipped out by sea , by air, by express as soon as possible once payment receipt.

Vanadium Nitride VN Powder Properties |

| Other Names | Vanadium nitride, Vanadium(III) nitride, VN powder |

| CAS No. | 24646-85-3 |

| Compound Formula | VN |

| Molecular Weight | 64.9482 |

| Appearance | black powder |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | 6.13 g/cm3 |

| Purity | 99.00% |

| Particle Size | 5-10um |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Modulus | N/A |

| Exact Mass | 64.947 |

| Monoisotopic Mass | 64.947 |

| | |

| | |

Vanadium Nitride VN Powder Health & Safety Information |

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us