Graphite is an older negative electrode material. Graphite is a more desirable negative electrode material than carbon materials. Its conductivity, crystallinity, and good layered structure are all better than those of other carbon materials.

Modifications: Improve the performance of anode material

Graphite Negative Electrodes generally use natural flake graphite. But there are a few drawbacks.

(1) Flake graphite has a large surface area which can have a greater effect on the first charge of the negative electrode and its discharge efficiency.

(2) The graphite layer structure determines that Li+ cannot penetrate the material’s end and diffuse into the particles. Flake graphite has an anisotropy that makes the Li+ diffusion path long and uneven. This causes a low specific ability.

(3) The graphite’s layer spacing is too small. This increases Li+’s diffusion resistance, but also makes it less efficient at delivering high rates of charge. Li+ is easy for graphite to form lithium dendrites and deposit it on the graphite’s surface. This can pose serious safety hazards.

Natural graphite can be modified to address these issues using technologies such as surface oxidation and surface fluorination. After taking into account cost and performance, industrial graphite modification is largely done using carbon coating. Modified natural graphite is a commercially available material with a specific capacity between 340 and370 mA*h/g. This has a coulombic efficiency in excess of 93% in the first week. The DOD cycle time of over 1,000 times can also be used to supply small electronic products. Specific requirements for battery performance.

Innovation: Tap the Potential of Graphite Applications

People are continuously pursuing new technology in lithium-ion battery development, which is a result of the rapid development and use of 3C and other industry sectors. This will allow them to attain higher performance and a longer lifetime. This results in a higher graphite-anode requirement.

Graphite concentrate is able to be further processed to make graphite products. These include graphene (spheroidized graphite), flexible graphite (fluorinated graphite), nuclear graphite or silicon-impregnated graphite), and spheroidized graphite. This will allow graphite to be used in lithium batteries at a higher level. Graphene is a good conductor and can help reduce volume expansion in electrode materials. This will greatly increase the power batteries’ performance. Graphene is widely used as a positive electrode, negative electrode, current collector, separator, and conductive addition in lithium-ion cells. Future market opportunities are very broad and the current focus of research is graphene. Spherical graphite features good electrical conductivity and high crystallinity. It is used to replace negative electrode materials in the production of lithium ion batteries, both at home and overseas.

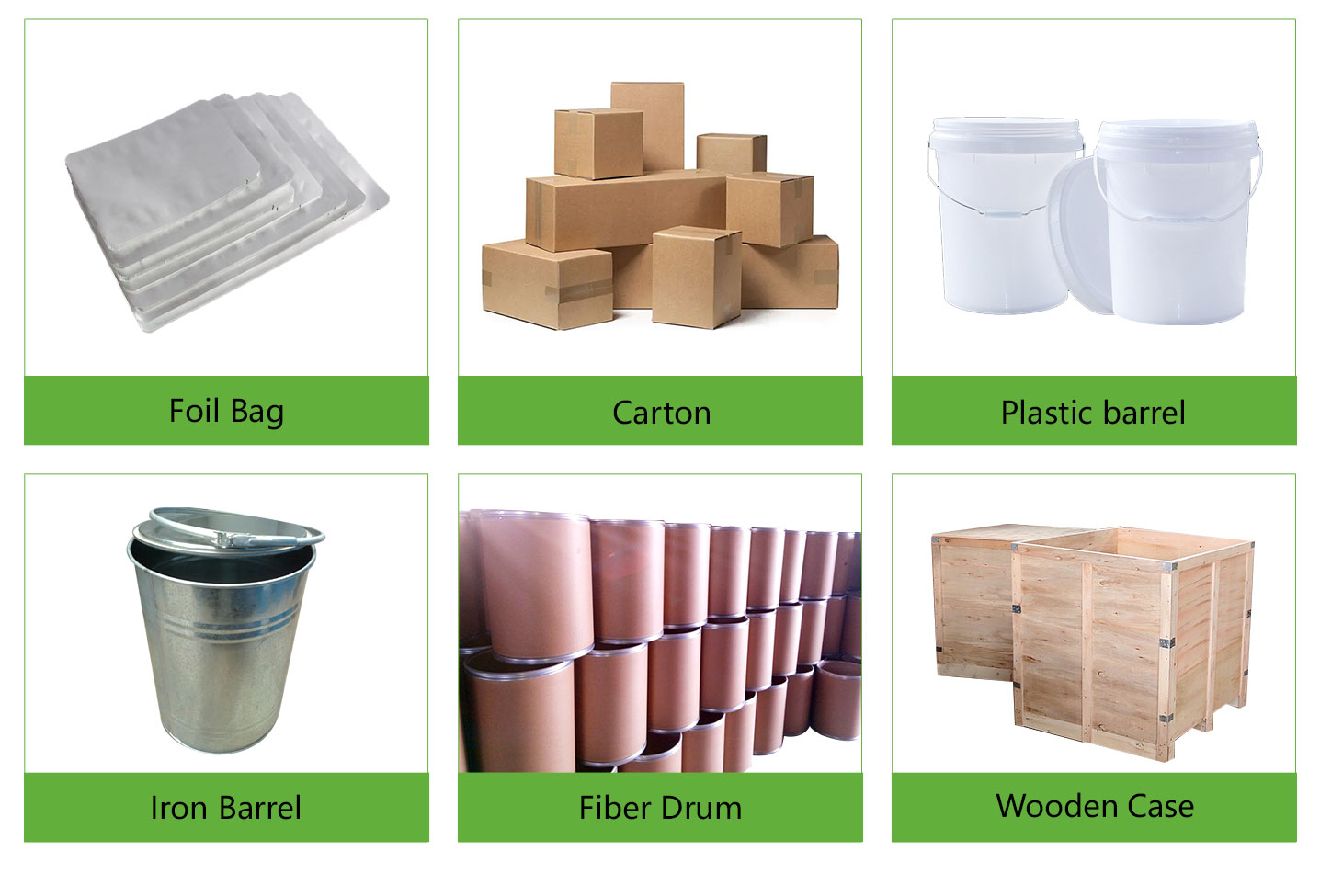

Tech Co., Ltd. is a professional supplier of graphite powder with more than 12 years’ experience in chemical products development and research. We accept credit cards, T/T and Paypal payments. We will ship goods overseas via FedEx, DHL and by air or sea to our customers.

Send an inquiry if you’re looking for titanium diboride powder of high quality.