About Cadmium Telluride Powder CdTe Powder:

The chemical formula of cadmium telluride is CdTe, the molecular weight is 240.00, and it has certain liver and kidney toxicity. The melting point is 1041℃, and it decomposes when the temperature is higher, and the relative density is 6.2015. It is insoluble in water and acid but can be decomposed by reacting with nitric acid. It is easily oxidized by air when wet.

Cadmium telluride (CdTe) is a stable crystalline compound formed from cadmium and tellurium. It is mainly used as a semiconductor material and infrared optical window in cadmium telluride photovoltaic cells. It is usually sandwiched with cadmium sulfide to form a p-n junction solar photovoltaic cell. Generally, CdTe PV cells use an n-i-p structure.

Bulk CdTe is transparent in the infrared, from close to its bandgap energy (1.5 eV at 300 K, corresponding to an infrared wavelength of about 830 nm) to wavelengths greater than 20 µm. Correspondingly, CdTe fluoresces at 790 nm. As the size of CdTe crystals is reduced to a few nanometers or less, so that they become CdTe quantum dots, the fluorescence peaks move to ultraviolet light in the visible light range.

CdTe is insoluble in water. CdTe has a high melting point of 1041°C and evaporates from 1050°C. The vapor pressure of CdTe at ambient temperature is zero. Due to its high melting point and insolubility, CdTe is more stable than its parent compounds cadmium and tellurium and most other Cd compounds. Feel free to send an inquiry to get the latest price if you would like to buy Cadmium Telluride Powder CdTe in bulk.

Product Performance of Cadmium Telluride CdTe Powder :

Cadmium telluride is a crystalline compound formed from cadmium and tellurium. It is sandwiched with calcium sulfide to form a p-n junction photovoltaic solar cell. It has very low solubility in water and is etched by many acids such as hydrobromic and hydrochloric acids. It is commercially available as powder or crystals. It can also be made into nanocrystals

Technical Parameter of Cadmium Telluride CdTe Powder :

Item | Purity | APS | Color | Atomic Weight | Melting Point | Boiling Point | Crystal Structure | Lattice Constant | Density | Thermal Conductivity |

Tr-CdTe | >99.99% | 100mesh | black | 240.01 | 1092°C | 1130°C | Cubic | 6.482 Å | 5.85 g/cm3 | 0.06 W/cmK |

Note: according to user requirements can provide different size products.

How is Cadmium Telluride Powder CdTe Powder produced?

The mixture of tellurium and cadmium is melted and sublimated in a hydrogen stream, or cadmium tellurite or tellurite is heated and reduced in a hydrogen stream. It can also be reacted by sodium telluride and a cadmium acetate solution acidified by acetic acid. It is brownish-red when precipitated, and almost black after drying. It can also be obtained by acting on cadmium vapor with hydrogen telluride to form a single crystal of cadmium telluride. Using high-purity tellurium and cadmium as raw materials, cadmium telluride is synthesized after deoxidation and then grown into a single crystal or polycrystalline by vertical crystallization method or vertical zone melting method.

Application of Cadmium Telluride Powder CdTe Powder:

CdTe is mainly used in solar cells, thermoelectric conversion elements, refrigeration components, thermal, photosensitive, piezoelectric crystals, nuclear radiation detection and infrared detectors. It can also be used in industrial additives such as semiconductor devices, alloys, chemical raw materials and cast iron, rubber, Glass, etc.

CdTe is used to make thin-film solar cells.

CdTe can be alloyed with mercury to make a universal infrared detector material (HgCdTe).

CdTe can be an excellent solid-state X-ray and gamma-ray detector (CdZnTe), where CdTe is alloyed with a small amount of zinc.

CdTe is used as an infrared optical material for optical windows and lenses and has been proven to have good performance in a wide temperature range.

CdTe is also used in electro-optic modulators. Among the II-VI compound crystals, it has the largest electro-optic coefficient in the linear electro-optic effect (r41 = r52 = r63 = 6.8×10-12 m / V).

CdTe doped with chlorine is used as a radiation detector for X-rays, gamma rays, beta particles and alpha particles.

CdTe can operate at room temperature, so a compact detector can be constructed for various applications in nuclear spectroscopy.

CdTe outstanding performance in realizing high-performance gamma-ray and X-ray detectors is its high atomic number, high charge collection and excellent spectral resolution

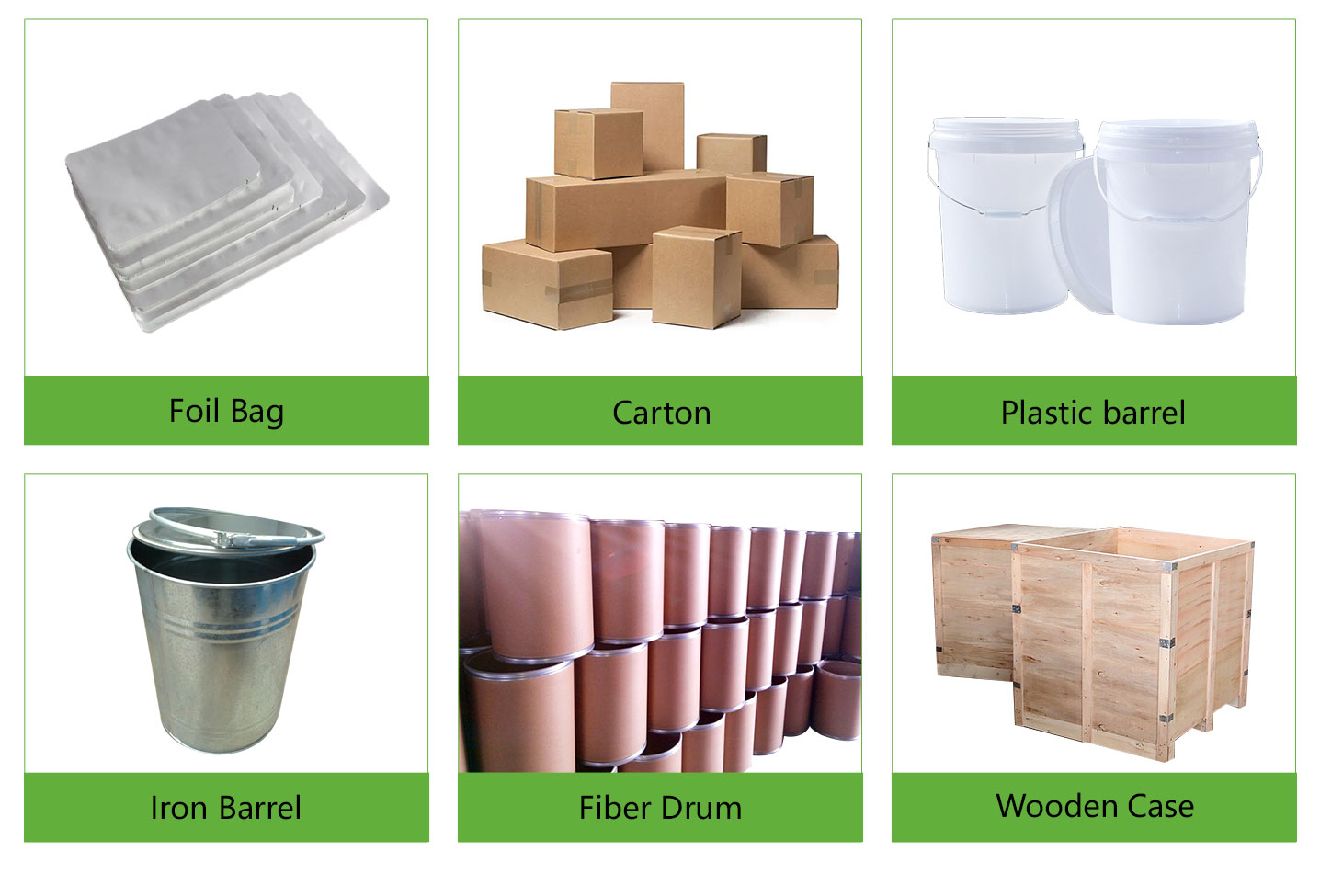

Packing & Shipping of Cadmium Telluride CdTe Powder :

We have many different kinds of packing which depend on the Cadmium Telluride CdTe Powder quantity.

Cadmium Telluride CdTe Powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Cadmium Telluride CdTe Powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Cadmium Telluride Properties | |

| Other Names | cadium monotelluride, tellanylidenecadimium, telluroxocadmium, CdTe powder |

| CAS No. | 1306-25-8 |

| Compound Formula | CdTe |

| Molecular Weight | 240.01 |

| Appearance | Gray Black Powder |

| Melting Point | 1090 ℃ |

| Boiling Point | 1130 ℃ |

| Density | 5.9 g/cm3 |

| Solubility in H2O | N/A |

| Poisson’s Ratio | 0.41 |

| Specific Heat | 210 J/kg-K |

| Thermal Conductivity | 5.0 W/m-K |

| Thermal Expansion | 5.9 µm/m-K |

| Young’s Modulus | 45 GPa |

| Exact Mass | 243.81 |

Molybdenum Telluride Health & Safety Information | |

| Signal Word | Warning |

| Hazard Statements | H302-H312-H332-H410 |

| Hazard Codes | Xn,N |

| Risk Codes | 20/21/22-50/53 |

| Safety Statements | 60-61 |

| Transport Information | UN 2570 6.1/PG 3 |