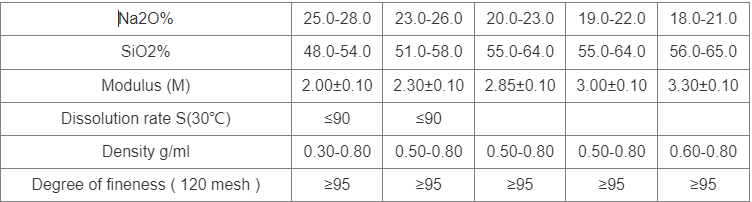

Technical Parameters of Powdered Split Second Sodium Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Keep in mind: We can likewise tailor sodium silicate powder with moduli of 2.45, 2.5, and 3.4 according to your requirements.

Our Variety Of Sodium Silicate Moduli

We offer powdered split second salt silicate with moduli varying from 2.0 to 3.3. Furthermore, we can tailor salt silicate powder with moduli of 2.45, 2.5, and 3.4 to satisfy your certain demands.

Sodium silicate, likewise known as water glass, has actually gathered significant passion owing to its vast array of applications across diverse sectors. Composed of salt oxide (Na2O) and silicon dioxide (SiO2), this substance can be discovered in types varying from strong granules to liquid options, depending upon the proportion of these two parts. Its unique attributes, consisting of solid adhesive homes, robust thermal stability, and acid resistance, render it a crucial material in industries such as building and construction, automobile manufacturing, and other production markets.

Versatile Uses Throughout Industries

In the building sector, sodium silicate serves as an essential part in concrete sealants and fireproofing agents, enhancing resilience and safety and security. It is additionally used in the production of adhesives and binders for making abrasive products and refractory products. In the automotive industry, sodium silicate is essential for making molds for casting engine elements since it can sustain high temperatures without deterioration. Moreover, its usage in water treatment procedures for softening tough water highlights its flexibility in dealing with ecological worries.

Environmental and Safety And Security Considerations

Despite its prevalent use, the handling of sodium silicate requires careful consideration of environmental and safety standards. While it is typically considered risk-free, extended exposure can cause skin irritation, and its dirt can aggravate the breathing system. Adherence to correct disposal techniques is important to avoid contamination of water bodies and the succeeding harm to aquatic organisms. Suppliers and users are significantly adopting sustainable techniques to mitigate the environmental impact of salt silicate manufacturing and usage.

( sodium silicate)

Final thought

The overview for salt silicate is brilliant as scientists remain to uncover brand-new usages and improve existing applications. Provided the ongoing technological improvements and the enhanced focus on sustainability, this multi-faceted substance is set to play an increasingly central role in driving industrial advancements. As markets evolve, so too will certainly the methods which salt silicate adds to satisfying the obstacles of the 21st century.

High-quality Sodium Silicate supplier

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sodium silicate production line, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us